An Overview of Factories:

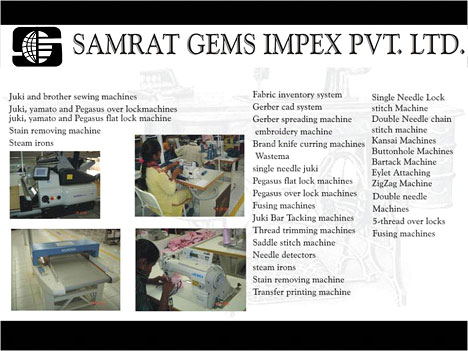

We have two state of the art factories in Bangalore & Bhiwandi (Mumbai) with a combined production capacity of over 4,50,000 (depending on style) Garments/month. Our Unit-I have 480 machines specially set to handle knitted and woven apparels where as Unit-Il has 400 machines set to take care of woven & knitted apparels including bottoms. The Employees are skilled and experienced and the systems have been set so as to organize quality controlled and efficient production. we have an in house technical team that works on enhancing productivity and achieving maximum economies of scale.Fabric department:

Fabric storage facility is very well organised with all the fabrics stored in racks with inventory control software , So that it minimize the extra time taken to search and check fabric in the storage facility.

Unit 1:

The factory has the latest Gerber cutting System (cad/spreadci/cutters). The cutting room is organized and set by Gerber consultants from UK and Australia making sure that the cutting room is functional with highest efficiency and minimum rejections. The fabrics are spread on air cushioned tables reducing stretching and making handling to the minimum. The cutting technology has been trained by professionals in the industry, and use the Gerber CAD Software which is recognized by the entire industry as one of the most reliable software enable us to minimize fabric wastage and achieve better utilization in cutting.

Industrial engineering department:

The high productivity is achieved by in house industrial engineering dept, which plans layouts and productivity according the styling, to ensure maximum productivity with minimum rejection. All the parts are assembled in the assembly lines and a time and motion study is done for each line, accordingly layouts are set.Workstations :

The complete sewing and finishing section is set up in the work station format with more than 700 workstations. By using the very latest automatic machines, these workstations are set to engineer productivity with the highest efficiency.Quality assurance team:

A QA team who report directly to the directors ensuring that at no given point of time there is a compromise in the quality for productivity. Quality control is exercised from the fabric stage at the point of dispatch from the mills. Based on the reports fabric is again checked and issued for cutting. Also before loading panels on the machines, each and every part is checked so as to minimize rejection during assembling of the product. Online checking station ensure stringent quality control before goods come into the finishingMechanics and maintenance:

The in house mechanics, electrician, maintenance and housekeeping teams ensure at no given point of time we have any production loss due to down time on machines, power etc;Embroidery Department..

The in house 9 colour embroidery machines can handle embroidery production of 8,000 – 10,000 units a day of embroidery / appliqué depending on the number of stitches. Also have an in-house punching and designing software for creating new designs as per requirement.Hand embroidery department:

Our facilities in Mumbai & Bangalore are capable of handling Multi dimensional products with heavy embellishments, prints and embroideries. We are exporting embroidered fabrics/accessories to U.S.A., Europe and Middle East. Some of our clients include: Bill, class, Gloria, Vanderbilt Blueprint, Marc Cain Etc..Laundry

In House Laundry with all kind of washes:( Acid wash. Softener/ Silicon! Enzyme wash) PP Spray washing & DryingMini LAB

Copyright © 2014 - Samrat Gems Impex -All Rights Reserved

Design by. SPG Techsoft